Pharmacy Workflow: How Medications Move from Manufacturer to Your Hand

When you pick up a prescription, you’re seeing the end of a long, complex chain called pharmacy workflow, the organized process that ensures the right medication reaches the right patient at the right time. Also known as medication distribution system, it’s not just about filling bottles—it’s about timing, safety, cost control, and constant coordination between manufacturers, insurers, and clinicians. This system has to work 24/7, even when generic drugs are delayed by patent tricks, insurance formularies change overnight, or a critical medication like lithium runs low. Every step—from how the active ingredient is made in India or China, to how it’s shipped across oceans, to how the pharmacy verifies insurance coverage—matters.

Behind the scenes, generic drug supply chain, the network that gets non-brand medications from factories to pharmacies. Also known as pharmacy drug sourcing, it’s where most of your prescriptions actually come from—90% of U.S. prescriptions are generics, but only 23% of spending. That’s because these drugs are cheaper, but getting them isn’t easy. Delays happen because of FDA backlogs, API shortages, or companies holding back production to keep prices high. Then there’s medication distribution, how those drugs physically get to your local pharmacy, often through regional wholesalers who manage inventory across hundreds of locations. Also known as pharmaceutical logistics, this part has to handle temperature-sensitive drugs like insulin, controlled substances like opioids, and fragile pills that break if handled wrong. A single mistake here can mean a patient goes without meds for days.

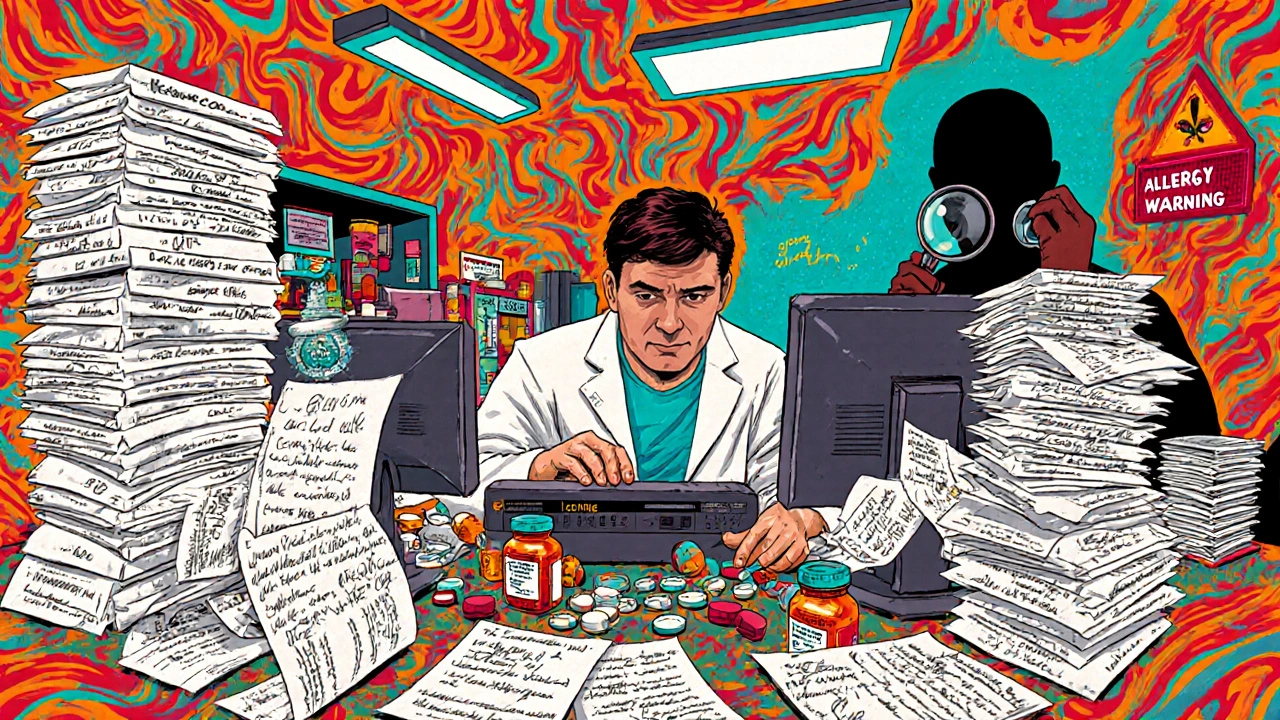

pharmacy operations, the daily routines inside a pharmacy that turn prescriptions into safe, accurate doses. Also known as pharmacist workflow, this includes checking for interactions, verifying insurance prior authorizations, counseling patients on side effects, and managing returns when a drug is recalled. It’s not just tech—it’s people. Pharmacists now spend more time on insurance battles than on clinical advice, thanks to formulary restrictions and prior auth requirements that block even cheap generics. And when a drug like selegiline or dapsone has rare side effects, the workflow must flag it before the patient even leaves the counter. Meanwhile, drug sourcing, how pharmacies choose which suppliers to buy from. Also known as medication procurement, it’s a balancing act: cheaper generics are great, but if they’re from a plant with bad quality control, the risk isn’t worth the savings. That’s why many pharmacies stick with trusted distributors—even if it costs more.

What you’ll find below isn’t just theory. These articles pull back the curtain on real pharmacy workflow issues: why your insurance blocks a generic you’ve used for years, how TSA handles your meds on a flight, why some drugs expire faster than others, and how supply chains break during shortages. You’ll learn how P&T committees decide what gets covered, how pharmacists spot dangerous interactions, and why a single pill can take years to reach the shelf after its patent expires. This isn’t a textbook. It’s what happens when science meets logistics, money, and human error—and how to protect yourself in the middle of it all.